Bespoke Polyurethane Components

We manufacture polyurethane products that are bespoke to your specific requirements.

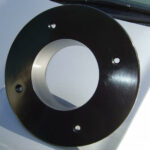

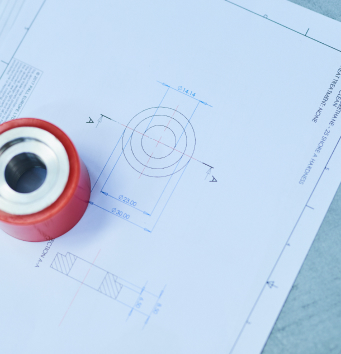

They are accurate to the mm, including producing tailor-made wheels, rollers, and tubes with pinpoint cut-outs, holes, and indentations that meet your exact requirements.

Getting your polyurethane part crafted to your exact specifications will ensure it slots quickly into place, performs brilliantly, and provides durability and reliability.

Agriculture

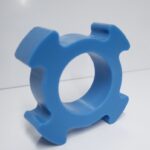

An increasing number of customers based in the Agriculture industry are making use of our quality Polyurethane manufactured components, such as slurry scraper blades and custom mud flaps. Polyurethane in agriculture has also become the choice material to replace metal star wheels used in harvesting. Durable and microbial-resistant Polyurethane is a superior choice over previous metal star wheels and other seed plantation components as it lasts longer and is more cost-effective. Polyurethane has grown in popularity, in the industry, due to its sound reduction properties, lightweight, and abrasion resistance.View AgricultureAutomotive

A regular on our production lines for the automotive industry are polyurethane bushing components. The range stretches from standard bushing components to wishbone rod bushes, axle link bushes, suspension bushes, bump stops, flexible couplings, drive couplings, snow chains, and more. Other custom-made components we supply include Polyurethane Carousel Slats, which we can mould into complex designs and include your company logo. Our Scraper Blades are custom-made from superior high-grade high abrasion abrasion-resistance Polyurethane in any colour. CMP manufactured dual hardness Polyurethane Magnetic sensor housing for the automated car park at Heathrow Airport Terminal 5, see our News post for more information on that project.View AutomotiveEngineering

Unleash the potential of your projects with our Engineering-focused polyurethane parts. From versatile seals to custom-moulded components, our solutions are crafted for precision and reliability. Elevate your engineering endeavours with our high-quality parts, designed to meet diverse application needs and contribute to the success of your innovative projects. Polyurethane is an extremely versatile, abrasion-resistant material making it perfect for the engineering industry.View EngineeringMines & Quarries

With toughness and resilience high on the agenda in the mining and quarry industries, Polyurethane products have become a key component for forklift wheels and impact bars, among other mining products. Polyurethane mining components can be manufactured with holes, slots, or metal inserts with no need for any drilling and are designed to withstand impact and abrasion. This makes PU perfect for a wide range of applications and gives a quarry or mine operator a high-performing, long-life product. We regularly manufacture quarry screens for screening and crushing machines in the quarrying industry and impact bars and pad hoppers receiving heavy loads of rock and aggregate.View Mines & QuarriesOil & Gas

Offshore polyurethane products manufactured by CMP Ltd can be designed and produced in-house to fit each customer’s unique product needs. We can create custom-moulded polyurethane products for various industries, including marine applications, oil & gas operations, and more. In addition to moulded polyurethane marine products, we can rebuild custom wheels and diablo rollers to your design specifications. We will also assist in the design of your custom polyurethane products, moulds, and inserts with our in-house engineering capabilities.View Oil & GasPaper & Cardboard

Paper pulp, cardboard manufacturing, and sheet production require machines with very high abrasion resistance. With technically complex processes and machine rollers, paper mills need the best quality covers for their conveyor belt rollers with sophisticated properties. Polyurethane is perfect for this process due to its superior abrasion resistance, high load-bearing strength, and wide range of sure hardnesses. At CMP we can manufacture Sun Feed Rollers, primarily used in the paper and cardboard manufacturing process, made to the Sun Industry Standard. We can also produce custom-sized warehouse rollers, cutting sticks, cardboard wheels, and feed rollers to your specific design, in a range of shore hardness and colours, to suit your requirements and recover old, damaged feed rollers with a new polyurethane cover.View Paper & CardboardStreet Furniture

CMP has been a major processor of custom moulded polyurethane, and Street Furniture is one of our growing divisions. We have worked closely with designers and have manufactured street bollards, verge markers, post and rail, and cycle racks to name but a few. Due to the longevity and resilience of polyurethane, it is widely used in the manufacturing of street furniture like flexible bollards and ground bollard housings. Its tough durable qualities can withstand impact from vehicles and its flexibility makes it able to bounce back to shape without leaving any signs of damage on the vehicle.View Street FurnitureWheel & Tyre

Revolutionize your wheels and tires with our Polyurethane Wheel and Tyre components. From resilient tire treads to custom-moulded parts, our solutions prioritise durability and performance. Our high-quality components are designed to enhance traction, reduce wear, and contribute to the overall reliability of your vehicle's wheels and tires. Choose excellence in automotive engineering with our precision-crafted components.View Wheel & TyreBlocks and Sheets

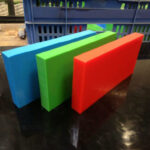

CMP manufacture solid blocks and rods in the full hardness range to meet your requirements. 80 shore A hardness and higher can be machined into components by the end user, such as bump stops, and bushes etc. If you’re not sure what type of Polyurethane block or sheet you need, our specialist team is here to advise on the right polyurethane sheet you may need for your particular application.View Blocks and SheetsEnd-to-End Polyurethane Manufacturers

Polyurethane Product Development

- 3D Visualisation

- Rapid Prototyping

- Tool making

Polyurethane Manufacturing

- Inhouse Tool & Mould Making

- High volume manufacturing

- 20,000 sq ft, UK factory

Ensuring Reliable Function

The level of tensile strength and flexibility can also be altered to match your commercial needs, as you can opt for bespoke polyurethane products that are highly malleable, through to items that are rigid and dense.

The reverse side of the coin is standard parts that appear to fit, but which slip, snag or slow down your processes (sometimes in hardly discernible ways).

In a nutshell, investing in bespoke polyurethane parts offers a good return on investment, by underpinning your productivity, and reducing the need for future maintenance and replacement.

Cost per unit Lower than you think

Another excellent reason to opt for bespoke polyurethane parts is that the cost is likely to be much lower than you expect!

With our expertise, equipment, and experience available to you, it is possible for tailormade parts to be designed, moulded, and finished off quickly without expensive R&D or set-up costs.

To put it simply, if you’re asking ‘Are bespoke polyurethane parts made to my specifications cost-effective?’ the answer is yes! We use highly economical manufacturing systems – and have readily available skills – to match your needs exactly, cheaply, and consistently.

How to source bespoke parts made from polyurethane

By ordering a bespoke polyurethane item, you can control not just the dimensions and gauge, but also such factors as resistance to harsh chemicals, oil, excessive moisture, or high friction applications.

Perhaps you need your machine part to function superbly but also dampen noise down or handle intensive friction or vibration, requiring a specific polyurethane mix.

Uniquely designed and manufactured polyurethane parts are simple to obtain if you get in touch with the responsive team at Custom Moulded Polyurethane.

We can discuss your exact specifications and expectations for the component or part. Then, we can quickly come up with a production solution and timetable.

Discover how we can help develop Polyurethane products for you

Let us know your requirements using the form below and we'll send you a free estimate within 48 hours.

"*" indicates required fields