Comprehensive Guide to Polyurethane Applications

April 18, 2024

Although you may not know it, at some point you will have encountered a polyurethane produ...

Read Full ArticleIf you were asked what is polyurethane you may well have a succinct answer. We throw the spotlight on some lesser-known facts about this highly versatile and prolifically used polymer. Polyurethane now plays a massive role in everyday life – featuring in everything from cushions to aircraft. It’s also a much-favoured substance for moulding manufacturing […]

If you were asked what is polyurethane you may well have a succinct answer. We throw the spotlight on some lesser-known facts about this highly versatile and prolifically used polymer.

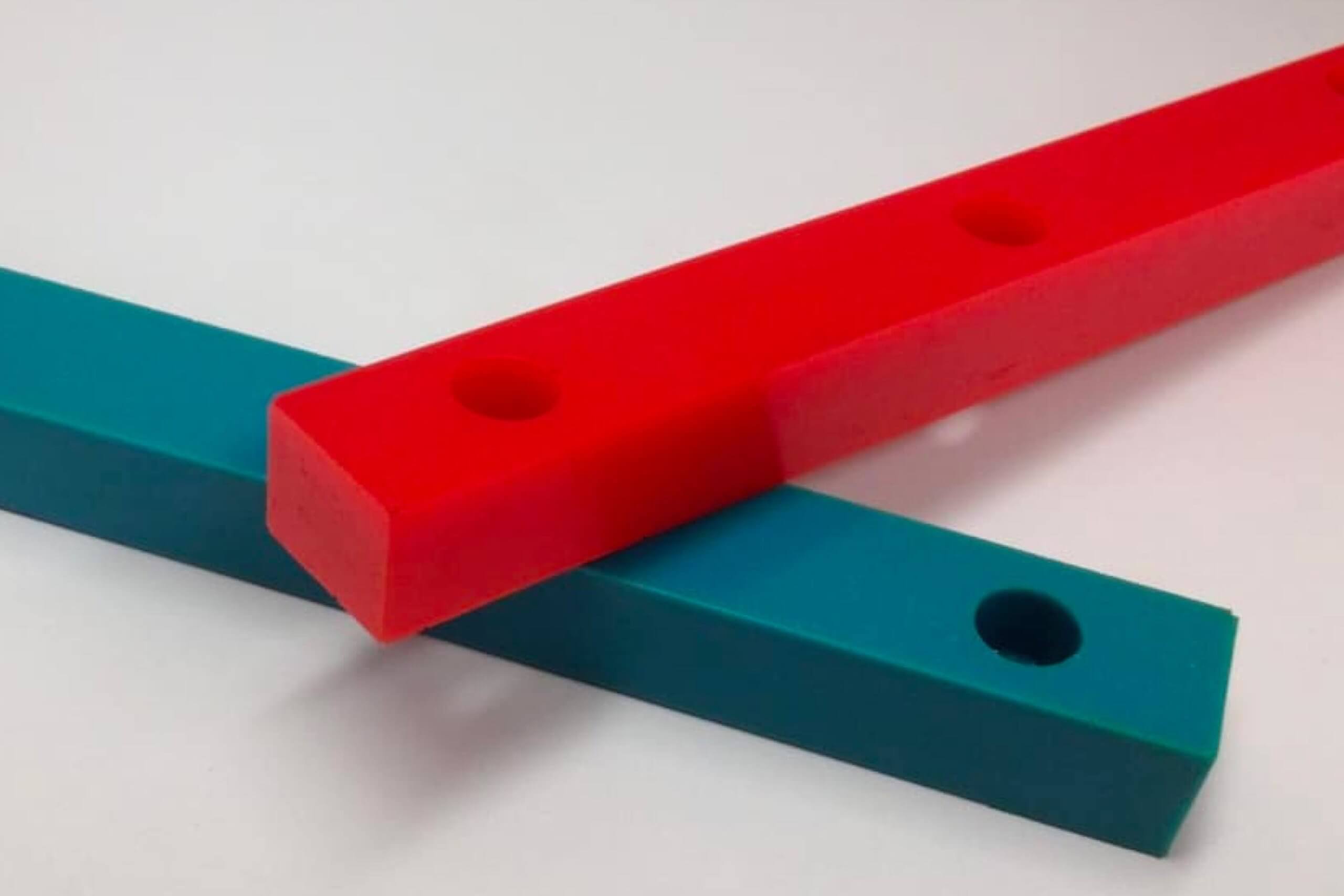

Polyurethane now plays a massive role in everyday life – featuring in everything from cushions to aircraft. It’s also a much-favoured substance for moulding manufacturing and engineering parts and components to enable the ‘wheels of industry to keep turning’. In fact, it’s literally used for wheels, runners and stops!

Yet sometimes Polyurethane is still a bit of a mystery.

To help illuminate this increasingly valuable synthetic substance, here are ten facts about polyurethane that may well surprise you.

Polyurethane is the material of choice for a diverse range of industry sectors seeking to innovate and manage costs. So, it’s easy to think of it – wrongly – as a highly modern material.

Who invented polyurethane, and when?

This extraordinarily versatile material for parts is often attributed to American chemist William Edward Hanford. He worked with Donald Fletcher Holmes in the 1930s on the catalytic process that achieves perfectly bonded polyurethane and patented this incredible invention in 1942.

However, you will also see the invention of polyurethane attributed to German chemist Professor Otto Bayer (1902-1982), who also worked on the concept in the 1930s. He is often referred to as the Father of polyurethane chemistry and received many patents and accolades for his work.

During the second world war, rubber was scarce, and this new organic polymer was the perfect alternative. It was used for everything from mustard gas resistant clothing to high-gloss aeroplane finishes.

By the mid-1950s polyurethane was being mass-produced to use as a coating, adhesive and rigid foam. In the same decade, the option to vary its composition to create a soft foam was discovered. This led to its use in the construction of all sorts of seats and cushioning components, and ultimately to its popularity as a low-cost polyether polyol for use in contemporary upholstery and automotive applications.

It’s possible to manufacture polyurethane in an infinite range of ways, changing its structure and performance according to its blend of components, and the type of additives and catalysts used. However, the two main categories of PU are polyester and polyether.

It’s possible to manufacture polyurethane in an infinite range of ways, changing its structure and performance according to its blend of components, and the type of additives and catalysts used. However, the two main categories of PU are polyester and polyether.

These are both elastomers, and the biggest difference between polyester vs. polyether is their performance.

Polyester can withstand high temperatures for even longer, holding its shape and flawless surface. However, it’s less resistant to moisture than the other form of polyurethane.

Polyether has an increased ability to withstand cold temperatures and moisture, and it is also resistant to heat caused by friction, Making it an ideal material for fast-moving wheels, or outdoor applications, for example.

Working with a specialist provider of bespoke polyurethane products, you can confidently match any item’s performance with a polyurethane solution. As well as getting a part that is perfect in terms of dimensions and tensile properties.

Related article: What is street furniture and what is it made from?

What is polyurethane made of? It’s a combination of polymers (which have a long chain of molecules) and urethane (which is a manmade synthetic crystalline). When mixed, they bond in a way that even makes them heat, energy and moisture resistant.

The advantages of polyurethane are clear, including significant reasons to choose it instead of rubber, plastic, metal or wood.

The advantages of polyurethane are clear, including significant reasons to choose it instead of rubber, plastic, metal or wood.

However, the actual process involved in manufacturing polyurethane is highly complex. Not least as there are so many ways to vary its tensile properties; from a version hard as metal to pliant and soft foams, and strong coatings.

The secret is in the incredible chemical reaction that creates polyurethane. It involves mixing a diisocyanate (or a polymeric isocyanate) with a polyol (which is an alcohol containing more than two reactive hydroxyl groups per molecule).

By varying the diisocyanate and additives, you can achieve extremely diverse results. All sharing polyurethane’s strong structural bond and unrivalled durability.

Getting the ideal PU blend for each task is a skilled process. You also need specialist equipment and experience to create customised polyurethane moulding.

Related article: What are conveyor belt wheels made from?

There really is nothing like PU when it comes to versatility and by varying its mix and moulding it can take on a vast range of forms. This includes everything from liquids and foams, to super-strength parts that defy immense pressure and constant friction.

This is probably the least known of all polyurethane facts! The whole topic of why polyurethane is sustainable needs to be publicised more. Especially as many part specifiers are seeking environmentally-sound solutions that still manage unit costs brilliantly.

Many of the uses of polyurethane are linked to creating parts for machinery and to reinforce processes such as rollers for conveyor lines. However, when it is mixed to be a stable material and dried properly, polyurethane is safe enough to use in everyday situations in your home too! Even under environmental pressures, the stable versions release no toxins and or smells! Polyurethane does not alter PH in soil or water either. Though it is recommended that it is not used to mould eating implements, and the liquid form is highly poisonous.

PU foam manufacturing requires carbon dioxide and water – highly sustainable ingredients! Polyurethane is also a great insulator when you need materials that manage energy efficiency.

Read more: How the polyurethane industry helps the economy

This is possibly one of the less obvious ways to use polyurethane. The most obvious applications are solid and substantial forms of PU. This includes the exterior casings or covers of electrical items. However, it can be mixed and moulded to seal and insulate even the most fragile of components, including delicate wiring. So, it could be used as electronic instrument bezels as well as forming a protective exterior.

One superb illustration of just how versatile polyurethane comes in the form of human exercise. Gym equipment often incorporates PU moulded guards, stops or wheels. However, you might also be wearing clothes made of spandex, which is a highly elasticated type of polyurethane mix!

The creative manufacturers of polyurethane products are constantly finding new ways to mould its strongest and most dense form into highly energy-efficient construction materials. PU can be used to create seals and insulation products that herald ever-more sustainable buildings, such as rigid foam insulation panels.

As polyurethane is so commonly used for wheels, stops, bushes and other machinery and equipment parts – or as a foam in seating – its more innovative aspects can be overlooked. Including the possibility of using polyurethane as an adhesive agent or coating.

In fact, commissioning clear polyurethane as a topcoat is a great industrial opportunity. It can not only improve the appearance of items but will also protect the base coats. Remember, polyurethane is strong and resistant to moisture, moulds, abrasion, friction and extreme temperatures.

Various types of particles and fibres can be bound together using polyurethane. A great example of this is rebound carpet underlay. In some cases, a form of this incredibly versatile material is used to manufacture foam. Another form binds scrap pieces of that foam together to produce the protective and insulating material that goes under carpets.

Read more: What are polyurethane mouldings?

One application of polyurethane may particularly surprise you. It is commonly used to manufacture medical instruments and fittings, including items for hospitals such as catheter tubing, surgical drapes, wound dressings and bedding.

These facts about polyurethane show just how widely it is used, and in so many different forms!

Which leads to the question, can PU create the part you need for your project? Contact Custom Moulded Polyurethane as ‘the fact is’ that this is a universal solution to match any industrial need.

There are many myths and misconceptions about polyurethane. We explore some of the worst ones to show how safe and versatile this material is for a vast range of purposes and products.

Foams, adhesives, wheels, rollers, bushes, thermal insulating materials, soundproofing boards and super-strong supports and stops; the list of items that can be successfully formed from polyurethane is truly astounding. This versatile material features in every industrial sector you could think of, as well as being used for everyday applications such as car and furniture parts.

Yet, there are still some lingering misunderstandings about how polyurethane is made, how safe it is to use, and whether it’s low-cost means compromising on performance.

To set the record straight, we tackle five misconceptions about polyurethane.

With such a global push to reduce dependence on plastics, one of the most widespread myths about polyurethane is that it has the same negative environmental impact. Yet, polyurethane is not the same as plastic!

It’s a type of elastomer, which means it’s a polymer with elastic properties (like rubber) but it has the capacity to be produced with the strength of the metal.

In fact, due to its unique chemical structure, polyurethane is an eco-friendly alternative to plastic. That’s because it can be recycled successfully, breaking down its polymers leaving nothing that harms the environment.

Interestingly, polyurethane is also energy efficient to produce, and in skilled hands can be moulded and finished with adherence to lean manufacturing principles. Plus, when used in construction, it has important thermal properties to reduce energy waste.

Related article: Polyurethane: A Plastic or a Miracle?

This is another important misconception, as it could prevent you from exploring the many advantages of using polyurethane to create medical parts or components for children’s toys, for example.

It’s true that creating polyurethane is a skilled and complex process that requires careful handling of the chemical compounds used.

However, once it’s blended and formed, polyurethane is entirely stable. Which means it does not put toxic fumes into the atmosphere.

Keep in mind that it’s an incredibly durable and resilient substance too, so parts and components made from polyurethane won’t flake, shed or crumb – even under intense pressure and severe friction.

Polyurethane is also resistant to moulds, mildew and rot, making it a truly safe substance to use in house construction, as well as in products used in homes.

Related article: How the polyurethane industry helps the economy

Following on from the myth that polyurethane is toxic comes the incorrect hypothesis that its chemical structure makes it a fire risk. This is another occasion when the opposite is actually true.

If it does come into contact with flames, polyurethane won’t spread them but tends to dampen them down.

Interestingly, the composition of polyurethane makes it a great insulator, offering energy efficiency advantages as it traps heat inside a building. It’s also resistant to abrasion and friction and stands up to high temperatures without an issue.

All of which disproves the view that polyurethane is dangerous!

Related article: How Polyurethane helps Heathrow Airport run

One of the most common uses of polyurethane is automotive and engineering parts. As it is so strong and hardworking, it’s easy to see why.

Yet, there’s a lingering misunderstanding this doesn’t include high-performance bushes. The mistaken assumption is that polyurethane is too hard to create a smooth motion or a comfortable driving experience.

This flies in the face of the infinite possibilities of producing polyurethane to different tensile specifications. As well as the potential to create bushes from polyurethane with 100% accuracy. Meaning all steering and suspension targets can be met effortlessly when you produce bushes in polyurethane.

Related article: What is street furniture and what is it made from?

When you dig down on how polyurethane is made and the expertise invested in creating bespoke parts made from this versatile material, it’s easy to fall into a trap. Surely something this complex to produce as a durable customised part must carry a hefty price tag?

These are enduring misconceptions about polyurethane we are particularly keen to dispel. Thanks to our experience, expertise and investment in the latest equipment, Custom Moulded Polyurethane offers highly cost-effective precision engineering services.

You may well find that your polyurethane prototype – or a bulk order of PE parts – costs less than if you opted for alternative substances.

Test that for yourself, by getting in touch for a polyurethane part quote.

Let us know your requirements using the form below and we'll send you a free estimate within 48 hours.

"*" indicates required fields